Wire Rope Cable Fittings - Essential to Safety and Security When it comes to keeping things safe and secure, wire rope cable fittings are often key. These small parts may appear tiny, but they play an important and powerful role in the role of stability and durability.Ultimate Guide to wire rope cable fittings When you’re looking for wire rope cable fittings, you’ll want to know that there are popular and versatile fittings that are very useful in a number of different industrial situations, let’s look at the fittings that are a must have, how to make sure that you stay safe and secure with the right kind of cable fittings, as well as the strength and longevity in wire rope cable fittings. Finally, we'll wrap with choosing the best fittings for your wire rope requirements. WIRE ROPE CABLE WRAPS 7/16' X 20 SPIRAL WIRE GRAPPLE TRAILER/HAULER LOT OF 5 Rugged, durable steel construction Creates tight, secure connection to wire rope when going through standard cable with this rugged wraps Clamp on and hold securely with inside jaws Great for thousands of construction uses and many other applications Estimated delivery (bus = business days): Wilton, IA 2, Bus Davenport, IA 2, Bus Kansas City, KS 2, Bus PLEASE PROVIDE ZIP CODE WITH QUOTE.

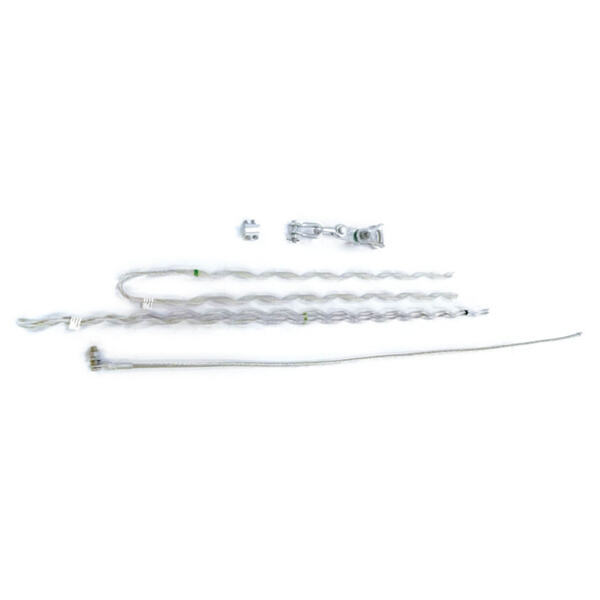

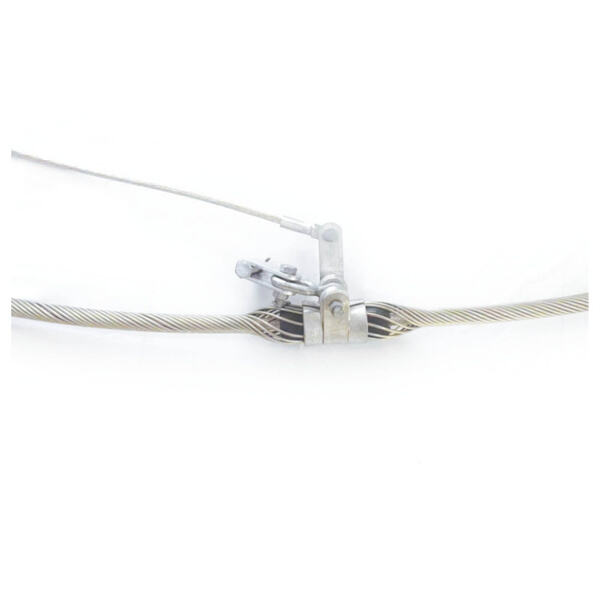

Applications: Wire rope is widely used in heavy industry for lifting and moving loads, such as cranes, for example. The best coupling is key to keep your wire in place on the vinyl cutter. Thimbles, clips, sleeves and turnbuckles are some of the primary metal fittings used to secure wire rope. These fittings also serve to keep the cable from fraying, secure the ends of the cable and also provide a stable anchor for the cable to be attached to. Wire rope cable fittings are available in many shapes in size for various industrial applications. Some of these fittings are for lifting heavy loads and some of them are for holding structures in place. Turnbuckles are great for adjusting the tension on a cable including tightening or loosening it, and can be used in a wide variety of fitting applications. Shackles are also common fittings, used to join two lengths of cable together, as well as attachment in anchoring and fixed ends.

Safety is the best policy when handling cable wire ropes. Fitting cable ends corretly will help to hold the cables tight so they will not slip. Thimbles These are helpful in forming a loop in the cable to keep the cable from fraying, unraveling or falling back out. Clips are another fitting that are useful to clamp the cable and stop it pulling out or being tugged.

Fittings for wire rope cable are constructed from sturdy materials such as stainless steel or galvanized steel to provide a long-lasting and robust solution. These products have the durability for heavy use and harsh conditions and can be used in industrial applications. The matching ends are also corrosion and wear resistant lasting a long time and will not have to be replaced in a long time. This hardiness and durability mean that the cables stay safe and intact at all times, without a hitch.

When selecting fittings for your wire rope products, you need to consider the specific requirements of the job. For instance, if you're working with heavy loads, you should try to get a fitting that can handle the weight. If you are working in corrosive atmosphere, you will need fittings which are anti- rust and corrosion. The size and type of the cable you are using will also need to be taken into consideration as varying fixtures are created for various cable types. By selecting the proper fitting for your wire rope you ensure that your cable is held in place so that it is safe to operate.