There are various types of these tension clamps for different uses. Understanding how to install and use tension wire clamp is crucial for facilitating good performance of the clamps. We will look at the importance of tension clamps in industrial processes, how to install and use them correctly, the benefits of tension clamps, different types of tension clamps available, and the maintenance and troubleshooting of tension clamps.

Tension clamps are known in industry for use in securely holding articles in position. They are widely used in the construction and manufacturing industries to fasten materials together. Tension clamps are used to hold things together and keep them tight and from moving. In absence of tension clamps, safe and efficient fastening of parts in different industrial applications would be a real problem.

Tension clamps should be installing and using correctly to operate well. The first step is to choose the appropriate type of constant tension radiator hose clamps for the task at hand. Once you’ve selected the right clamp, install it per the manufacturer’s guidelines. Ensure the clamp is firmly attached and fully tensioned. Check the clamp periodically to be sure it is still gripping objects tightly. Correct installation and usage of tension clamps is necessary for a safe and efficient work place.

Clamping under tension is highly advantageous for industrial purposes tension hose clamps provide excellent holding force, to prevent the object from shifting or pulling out. This preserves the integrity of the items held together and keeps a secure atmosphere. Moreover, the use of tension clamps helps to increase productivity and save time, as the routine of securing the workpiece is simplified. To sum up, tension clamps are essential carrying out the operation under fixed clamping condition, which is not only reliable but also safety in many industrial fields.

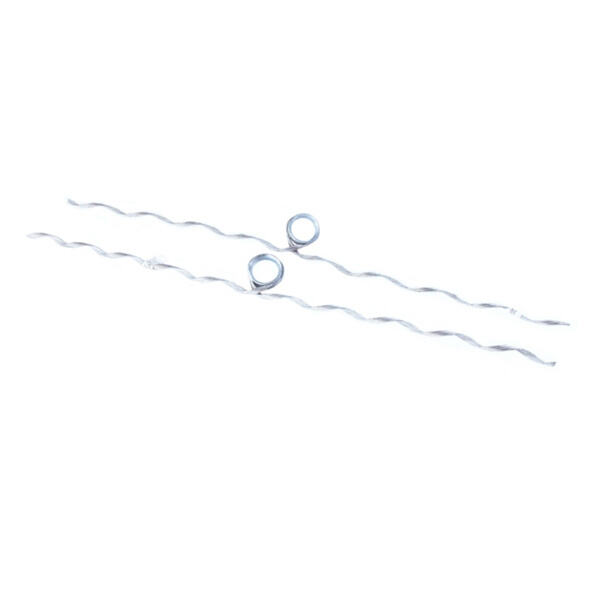

There are a few cable tension clamp that are used in the industry. Some of the most common variations are toggle clamps, spring clamps, and band clamps. Toggle clamps are for fastening at work pieces, and spring clamps are used for holding flat objects together. Band clamps are flexible and form to a wide variety of shapes. There are special characteristics and advantages for each type of tension clamp that makes them useful for a variety of applications.

For proper performance tension clamps need to be maintained. A common problem with spring tension clamps is so called relaxing of the clamp in time. So the fix for this is to occasionally tighten the clamp so that the desire amount of tension is maintained. Examine the clamp for damage and replace rusted or damaged parts. Regular cleaning of the clamp can also help not allow for any build-up that may hinder its function. Moreover, you can use these problem solving ideas to maintain high performance levels of your tension clamps so that they don’t ever lose integrity and are strong enough to clamp properly.