Have you ever seen the wires that span the sky and bind various locations? These vibration damper also play a key role in connecting us and delivering electricity to our homes. But did you know that those cables also might vibrate and screw things up? Enter cable vibration dampers!

Cable vibration dampers are used to damp the vibrations in cables. These vibrations may be due to a variety of reasons such as wind creating turbulence, ice layers, and even the load of the cables. When cables get too jumpy, it can cause problems like power failures or even break the cables.

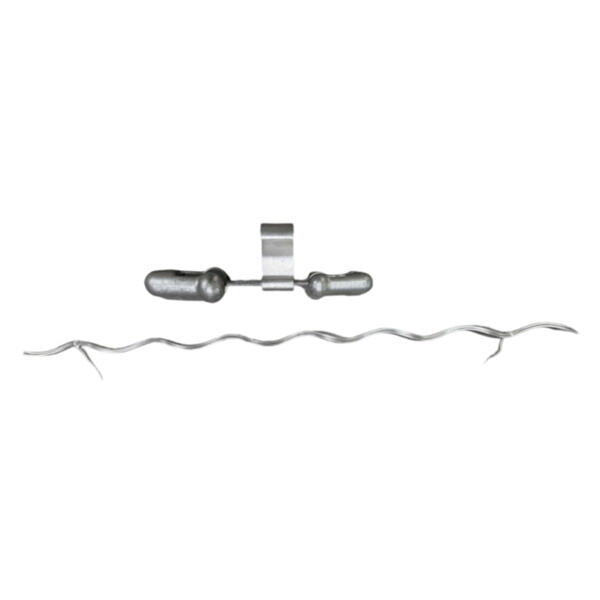

Transmission line efficiency can be substantially enhanced by the application of HONGZHI cable vibration dampers. These Spiral Vibration Damper are used to minimize the movement of the cables, thus preventing damage, and allowing the cables to continue functioning as intended. "Implicit within that is the ability to pass electricity more efficiently on the grid, providing more reliable power for everyone."

Cable Dampers – Damp the Vibration in Cables Cable vibration dampers simply absorb the energy that is causing vibrations in the cables. This helps minimize vibration and movement of the cables. There are various types of dampers which may be applied, depending upon the specific requirements of the transmission line. DAMPERS Some dampers are to be placed directly on the cables with which aeroelastic vibrations are to be controlled, while others are to be attached to towers supporting cables.

When transmitting electricity, safety is always an utmost concern. HONGZHI Vibration dampers for cables are indispensable in order to guarantee the safety and reliability of high-voltage power lines. Cutting down on the hum of the cables, these dampers avoid accidents and ensure that the electricity can flow undisturbed. This is particularly significant during high winds when the cables will be more prone to greater levels of vibration.

A range of advantages can be realized by the application of HONGZHI Vibration Damper to infrastructure works. These dampers not only serve to enhance the efficiency and reliability of the transmission lines, but also serve to prolong the life of the cables. When there's less stress and strain on the cables, this can also reduce wear and tear and possible down time and repair cost.